Description

Overview

Essential details:9907-1200 CPC-II current-pressure converter

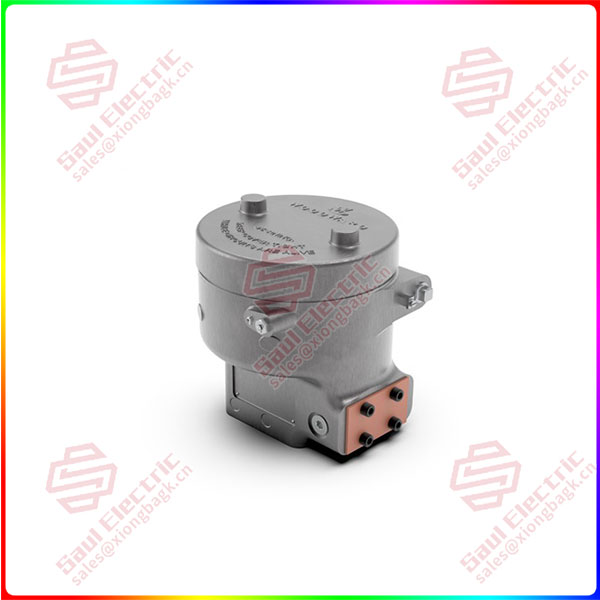

CPC-II(second generation current-Pressure Converter) is an electro-hydraulic pressure regulator designed for the control of single acting steam turbine valve servo. The excellent accuracy and resolution of the CPC-II make it an ideal regulator for steam turbine valves and their associated turbine speed and load control. The CPC-II accepts a given pressure signal of 4-20 mA and precisely converts it to control the oil pressure to position a single-acting steam turbine regulator. The precise and stable steam valve control directly improves the speed and load control performance of the steam turbine, and reduces the mechanical wear of the system.

The redundant nature of the CPC-II makes it ideal for critical steam turbine applications. The converter can be configured to accept several additional pressure given inputs from one or two (redundant) controllers and vote on this input. In addition, CPC-II can be configured to accept signals from both internal and external oil pressure sensors, voting to use the normal one.

The CPC-II’s durable design (powerful actuators, corrosion-resistant materials, one-way rotary valves, self-cleaning features) makes it ideal for challenging applications such as dirty or contaminated oil.

In addition, two controllers can be connected to a single CPC in several master/slave modes, which allows the turbine to continue operating or replace the controller online if one of the controllers fails. The design includes completely redundant applications, and any two CPC-iis can also be used in double redundancy to simplify the system and control circuits.

9907-1200

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

9907-1200 CPC-II current-pressure converter

CPC-II is an electro-hydraulic pressure regulating valve controller that uses a high-precision internal pressure sensor and PID controller to achieve accurate control of steam turbines. CPC-II consists of a valve-actuator assembly, a pressure sensor, and an electronic drive module. The electronic drive module accepts one (or two)4-20 MA pressure setpoints and compares these setpoints with the oil pressure measured by the sensor to precisely control the oil pressure of the turbine valve.

The CPC-II controller oil pressure is output through the oil supply end to the control oil pressure output end (turbine regulating valve control oil) or back to the system oil station. The converter’s unique PID system allows it to provide stable pressure control under normal conditions, providing a millisecond response to step changes in valve position in transient system or plant conditions. As a way to protect the turbine, in the event of any internal equipment failure (power input failure, pressure sensor failure, processor failure, etc.), the internal valve return spring forces the CPC-II to the fail-safe position (oil guide to drain end) and safely closes the turbine control valve.

CPC-II utilizes computer-based service tools to implement factory and/or field configurations. The CPC-II PCI Service Tool uses a simple user-friendly interface to allow users to easily configure, calibrate, and adjust internal functions and Pids. In addition, the CPC-II includes a 4-20 MA output channel to display the controller oil pressure, and can also enable system alarm, shutdown relay outputs to be connected to the system controller or plant DCS to indicate equipment status:

1 Year Warranty

1 Year Warranty