Description

Overview

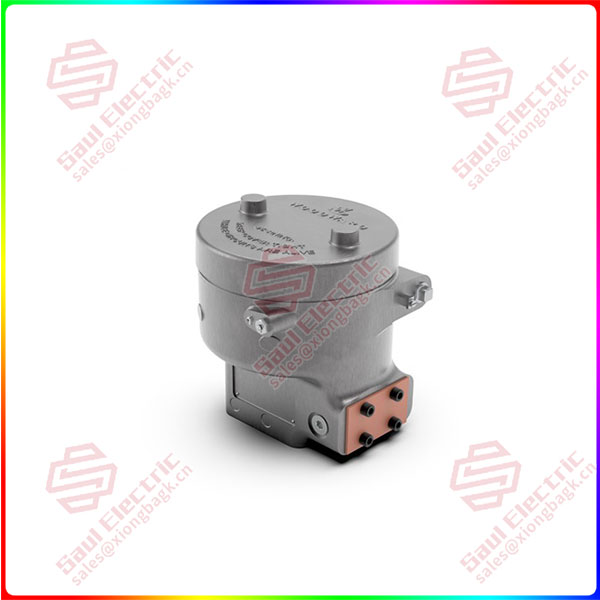

Essential details:9907-1200 current to pressure converter, generation II

The CPC-II (current to pressure converter, generation II) is an electrohydraulic pressure-regulating valve control designed for use in positioning single-acting steam turbine valve servos. This CPC’s superb accuracy and resolution make it ideal for steam turbine valve control and related turbine speed and load control. The CPC accepts a 4–20 mA pressure demand signal and accurately controls oil pressure to precisely position single-acting steam turbine governor-valves. Precise and stable steam valve control directly relates to improved steam turbine speed and load control and reduced system mechanical wear.

The CPC’s redundancy features make it ideal for critical steam turbine applications, where turbine up-time and availability are essential. This converter can be configured to accept redundant pressure demand inputs, from one or two (redundant) controllers, and vote the input to follow. Alternatively the CPC can be configured to accept signals from both its internal oil pressure sensor and an external (redundant) oil pressure sensor, and use the voted healthy signal.

The CPC’s robust design (strong actuator, corrosion-resistant material, single moving rotary valve, and self-cleaning port design) makes it ideal for challenging applications where dirty or contaminated oil may be present.

Optionally two controllers can be connected to a single CPC in a redundant Master/Slave fashion to allow the turbine to continue to operate if either turbine control fails, or on-line changes are desired. Designed for use in applications requiring full redundancy, optionally two CPCs can be applied in a dual-redundant fashion, simplifying the entire system and control wiring.

Description

The CPC is an electrohydraulic pressure-regulating valve control that utilizes a very accurate internal pressure sensor and PID controller to precisely control steam turbine valves. The CPC consists of a valve-actuator assembly, pressure sensor, and electronic driver module. The unit’s driver module accepts one (or two) 4–20 mA pressure setpoints and compares these setpoints to the sensed oil pressure, to accurately control turbine valve oil pressure.

The CPC controls oil pressure by porting supply-oil to its control-oil output port (turbine valve control oil) or back to the system supply tank. This converter’s special PID architecture allows it to perform very stable pressure control during normal conditions, and respond in milliseconds to desired valve step changes during system or plant transients. As a means of protecting the turbine, an internal valve-return-spring forces the CPC to a failsafe position (port oil to drain) and safely close turbine control valves upon any internal unit failure (electrical input power failure, pressure sensor failure, processor failure, etc.).

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

9907-1200 current to pressure converter, generation II

1 Year Warranty

1 Year Warranty