Description

概观

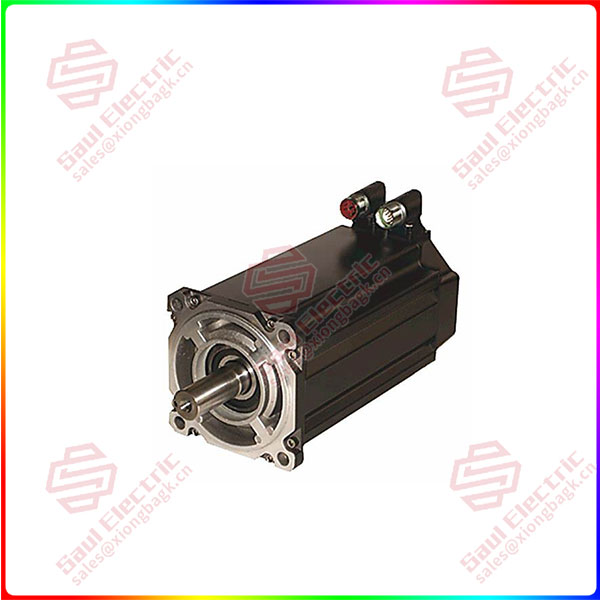

Essential details:MPL-B680B-M-X227 MP-Series Low-inertia Servo

Configuring a servo motor usually involves the following steps:

Determine the application requirements: First of all, it is necessary to clarify the application requirements of the servo motor, such as load type, load size, motion range, speed requirements, accuracy requirements, etc. These requirements will directly affect the selection of servo motors.

Select the right servo motor: According to the application needs, select the right type of servo motor. Factors that need to be considered include the rated power, rated voltage, rated current, maximum speed, maximum acceleration, etc.

Configure the drive: Select a suitable drive model and set the corresponding parameters. The driver is the key equipment to control the servo motor movement, which needs to set the correct control mode, pulse frequency, communication interface and other parameters.

Configure a feedback system: In order to achieve precise control, a feedback system needs to be configured, usually using encoders or sensors to detect the actual position and speed of the motor. It is necessary to select a suitable feedback sensor and configure the corresponding feedback mode and parameters.

Configure the upper controller: The upper controller is the core equipment to control the servo motor, you can choose PLC, motion controller or upper computer and other equipment. It is necessary to configure the corresponding control program and parameters to realize the communication and control with the servo motor.

Debugging and optimization: After the configuration is complete, it is necessary to debug and optimize to ensure that the movement of the servo motor meets the requirements of the application. This includes adjusting control parameters, optimizing motion trajectories, testing positioning accuracy, and so on.

MPL-B980C-MJ72AA

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

MPL-B680B-M-X227 MP-Series Low-inertia Servo

There are significant differences between servo motors and stepper motors in several ways:

Control mode: The stepper motor controls the rotation Angle by controlling the number of pulses, that is, a pulse corresponds to a step Angle. The servo motor controls the rotation Angle by controlling the length of the pulse time.

Workflow: Stepper motors usually require two pulse signals, namely signal pulse and direction pulse, in order to start working. Servo motors are much simpler, requiring only a power switch.

Low frequency characteristics: When the stepper motor is running at low speed, it is prone to low frequency vibration. In order to avoid this phenomenon, it is usually necessary to use damping techniques or subdivision techniques. However, the servo motor is very smooth at low speed and does not vibrate.

Torque frequency characteristics: the output torque of the stepper motor will decrease with the increase of the speed, and will drop sharply at higher speed, so its maximum working speed is generally 300 ~ 600r/min. The servo motor has a constant torque output characteristic, that is, within the rated speed (generally 2000 or 3000r/min), the output rated torque, and above the rated speed is a constant power output.

Overload capacity: Stepper motors generally do not have overload capacity, while servo motors have strong overload capacity.

Accuracy and responsiveness: The accuracy of a stepper motor is generally superior to that of a servo motor because it does not accumulate errors. However, servo motors are superior to stepper motors in terms of responsiveness.

Dynamic response: The servo motor has better dynamic response and stability, which can quickly respond to external control signals and achieve accurate position and speed control. In contrast, the stepper motor is prone to vibration and shock during high-speed movement and acceleration and deceleration.

Application scenarios: Servo motors are suitable for applications requiring high accuracy, speed and response, such as robotics, CNC machining, etc. The stepper motor is suitable for low-cost, low-precision control occasions, such as printers, vending machines and so on.

In summary, there are obvious differences between servo motors and stepper motors in terms of control mode, workflow, low frequency characteristics, moment frequency characteristics, overload capacity, accuracy and responsiveness, dynamic response and application scenarios. Therefore, when choosing a motor, it is necessary to decide which type of motor to use according to the specific application needs.

| IS420ESWBH3AX GE Analog I/O modules | 147663-01 BENTLY Communication analog output module |

| 516TX 336A4940DNP516TX GE 516TX-A Industrial Ethernet Switch | 125800-01 Bently Nevada Key phase input/output module |

| 128277-01 Future Expansion Faceplate Bently Nevada | 140471-01 Bently Nevada Developed I/O module with internal terminal |

| A413139 PC BOARD CIRCUIT BOARD MODULE ASSEMBLY METSO | 3500/22M 138607-01 Bently Detector module |

| D201471 Metso RT node PC AP31 D200137 personality module | 3500/94 145988-01 BENTLY Display module |

| A413188 PC BOARD CIRCUIT BOARD MODULE ASSEMBLY METSO | 3500/42M 176449-02 bently nevada Shaft vibration module |

| A413331 PC BOARD CIRCUIT BOARD MODULE ASSEMBLY METSO | 3500/92 136180-01 bently nevada Communication gateway module |

| D201466 Metso RT node PC AP31 D200137 personality module | 136180-01 Bently Nevada Communication gateway module |

| 85UVF1A-1QD Fireye Integrated Flame Scanner with Internal Flame Relay | 3500/92-03-01-00 Bently Nevada 3500/92-03-01-00 |

| 516TX 336A4940DNP516TX GE A microprocessor device | 7264 ABB The four-channel SSI interface module features automatic |

| 516TX-336A4940DNP516TX GE microcontroller | MDB-8E SARTORIUS Load cell |

| 2MLR-CPUHT HONEYWELL CPU HT bus function | 3500/15 127610-01 Bently Nevada Digital input module |

| 177313-01-01 BENTLY NEVATA Vibration monitoring module | 3500/50 133388-02 BENTLY NEVADA Tachometer monitoring module 4 channels |

| PXIE-6556 NI Automatic industrial control module | 3500/40-03-00 176449-01 BENTLY NEVADA Expansion axial position module |

| PFCL201CE ABB Pressure sensor controller | 3500/15 Plastic panel BENTLY NEVADA Ac and DC power supplies |

| MTL BPHM64 Eaton Safety grid base plate | X20CP1586 B&R The core product of B&R’s I/O system line |

| 1794-IF4IXT Allen Bradley Flex I/O 1794 series input module | IC698PSA350 GE High capacity power module |

| 1734-IM4 Allen Bradley POINT I/O 4 Point Digital Input Module | VMIVME 3215-000 GE Computer module |

| 1769-ECR Allen-Bradley Right end cover (ECR) module used together | 201TI GE Microprocessor-based electrical transmitter |

| 136188-02 Bently Nevada Ethernet /RS232 Modbus I/O module | 3500/05-01-02-00-00-01 BENTLY System rack |

| AI02J ABB Analog input module | PM865K02 ABB controller |

| DSSA165 ABB Ac power module | 3500/22-01-01-00 138607-01 BENTLY Transient data interface before and after the size card module |

| PXIe-1073 NI PXI Chassis | IS420UCSBH4A GE Controller module manufactured by General Electric |

| F860-CA HONEYWELL Series C “fieldbus interface module | D201376 METSO Analog input module |

| DSSA165 ABB Ac power module | D201376 METSO Analog input module |

| 125840-02 Bently Power module | IS420UCSBH4A GE Controller module manufactured |

1 Year Warranty

1 Year Warranty