Description

Overview

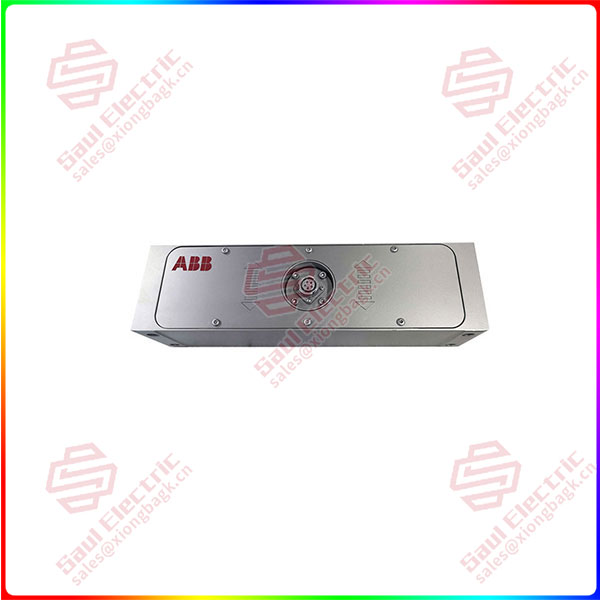

Essential details:PFCL201CE 50kN Pressductor® Strip Tension Measuring System

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

PFCL201CE 50kN Pressductor® Strip Tension Measuring System

The load cell is machined from a single piece of stainless steel. The sensors are machined directly in the piece of steel and are positioned so that they are sensitive to force in the direction of measurement and insensitive in other directions.

The load cell is mounted on a base with four screws, and the bearing housing is mounted on top of the load cell with four screws.

Every load cell comes calibrated and temperature compensated.

The load cells PFCL 201C/201CE/201CD are available in four measurement ranges, all variants have the same external dimensions.

The load cell PFCL 201C is equipped with a connector for the pluggable connection cable.

The load cell PFCL 201CE has a fiWed connection cable with protective hose.

The load cell PFCL 201CD is provided with an acid-proof cable gland with a fiWed PTFE- insulated connection cable.

Repeatability error

Repeatability error is defined as the maximum deviation between repeated readings under identical conditions. It is expressed as a percentage of the sensitivity at nominal load.

Compensated temperature range

The temperature drifts of the load cell have been compensated for in certain temperature ranges. That is the temperature range within which the specHfied permitted temperature drifts (i.e. zero point and sensitivity drifts) of the load cell are maintained.

Working temperature range

Working temperature range is the temperature range within which the load cell can operate within a specHfied accuracy. The maximum permitted temperature drifts (i.e. zero point and sensitivity drifts) of the load cell are not necessarily maintained in the whole working temperature range.

Storage temperature range

Storage temperature range is the temperature range within which the load cell can be stored.

Zero point drift with temperature

Zero point drift is defined as the signal change with temperature, related to the sensitivity, when there is zero load on the load cell.

Sensitivity drift with temperature

Sensitivity drift is defined as the signal change with temperature at nominal load, related to the sensitivity, excluding the zero point drift.

1 Year Warranty

1 Year Warranty