Description

概观

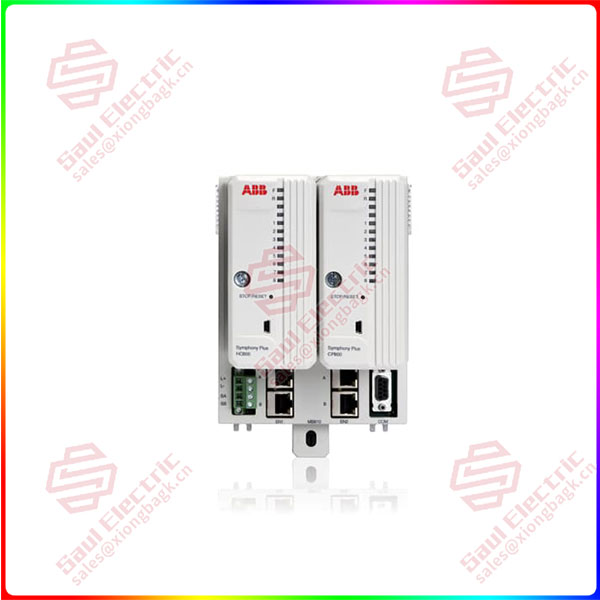

Essential details:PNI800 Plant Network Interface Module

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

PNI800 Plant Network Interface Module

The S+ Controller HPC800 is a high performance, high capacity process controller designed to meet the needs of workers Plant control needs range from decentralized and continuous control to batch and advanced control applications

The HPC800 controller can perform highly demanding process control in both data and logic processing System application. From the controller, I/O to the communication level can achieve redundancy, so as to maximize the efficiency

High system flexibility and availability. With a range of I/O modules, the HPC800 provides strength for factory applications of all sizes Large, diverse and flexible automation solutions.

The HPC800 can connect both DIN rail I/O modules and traditional rack-mounted I/O modules

A piece. Through industry standard fieldbuses and networks, intelligent I/O devices, such as smart transmitters, are implemented

Actuators, intelligent electronic devices (IEDs) as well as third party PLCS can be easily integrated into the system

Inside. The data information of each device can be used for control strategies and more advanced applications to ensure more Flexible, more reliable control solutions.

The HPC800 controller uses ABB’s complete set of successfully applied standard function code algorithms and S+ Engineering’s graphic design tools work together to implement their control strategies while supporting the including A variety of programming languages including C, Batch 90TM, UDF (User-Defined function code). tong Used with the same rack-mounted controllers as Symphony Plus, Harmony, and INFI90

The function code algorithm, HPC800 can be directly utilized in simple, secure, and mature application solutions.

The controller’s industrial-grade embedded system architecture enables the HPC800 to operate under 250ms Closed-loop control of more than 5,000 I/ OS in time. The characteristics of low power consumption enable it to be dense Seal installation without the need for fans, skylights, air filters and other forced cooling technologies. this Many potential failure factors are avoided so that the reliability and availability of the controller are improved High. In short, the HPC800 provides the user with fast, accurate, undisturbed process control Advantages.

S+ Operations, S+ Engineering and other applications pass through the system at high speeds 100 megabit high-speed Ethernet redundant communication factory network with high degree, high coverage and high security level (PN800) Communicates with the HPC800 controller. The network-centric structure enables field devices to pass Process control and electrical systems, plant management systems can be simple, flexible, seamless, and safely integrated Put it all together.

1 Year Warranty

1 Year Warranty