Description

Overview

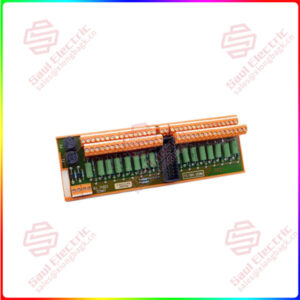

Essential details:PP885 3BSE069276R1 Compact Product Suite Panel 800 Version 6

DESCRIPTION

All Panel 800 Version 6 are developed to satisfy the demands of human-machine communication. Built-in functions such as displaying and controlling text, dynamic indication, time channels, alarm and recipe handling are included.

The Panel 800 Version 6 works primarily in an object-oriented way, making it easy to understand and use. Configuration is carried out on a PC using the Panel Builder configuration tool. The project can then be transferred and stored in the operator panel itself.

Various types of automation equipment such as PLCs, servos or drives can be connected to the Panel 800 Version 6. In this manual, the term “the controller” refers to the connected equipment.

This manual explains how to install the operator panel. Please refer to the Panel Builder Programming and Installation manual for further information.

• The operator panel is designed for stationary installation on a planar surface, where the following conditions are fulfilled:

– no high explosive risks

– no strong magnetic fields

– no direct sunlight

– no large, sudden temperature changes

• Install the operator panel according to the accompanying installation instructions.

• Ground the operator panel according to the accompanying installation instructions.

• Only qualified personnel may install the operator panel.

• Separate the high voltage, signal and supply cables.

• Make sure that the voltage and polarity of the power source is correct before connecting the operator panel to the power outlet.

• Peripheral equipment must be appropriate for the application and location.

• In a Zone 2 environment, this equipment shall be installed in an enclosure that provides a degree of protection not less than IP 54 or greater than IP 65 in accordance with IEC/EN 600079-0. The IP rating of the equipment is limited to the IP rating of the enclosure it is to be installed into.

• In a Zone 22 environment, this equipment shall be installed in an enclosure that provides a degree of protection not less than IP 64 or greater than IP 65 in accordance with IEC/EN 600079-0. The IP rating of the equipment is limited to the IP rating of the enclosure it is to be installed into.

PP885 3BSE069276R1

Product parameter

• The agreed warranty applies.

• Before carrying out any cleaning or maintenance operations, disconnect the equipment from the electrical supply.

• Clean the display and surrounding front cover with a soft cloth and mild detergent.

• Replacing the battery incorrectly may result in explosion. Only use batteries recommended by the supplier. During the warranty period, the battery needs to be replaced by an authorized ABB service center.

APPLICATION

Connect the cables in the specified order, according to the drawing and steps below.

• The operator panel must be brought to ambient temperature before it is started up. If condensation forms, ensure that the operator panel is dry before connecting it to the power outlet.

• Ensure that the operator panel and the controller system have the same electrical grounding (reference voltage level), otherwise errors in communication may occur.

• Ensure that the voltage and polarity of the power source is correct.

• Separate high voltage cables from signal and supply cables.

• Shielded communication cables are recommended.

– Connect cable A.

– Connect cable B, using an M5 screw and a grounding conductor (as short as possible), that is sized correctly according to local electrical codes.

– Connect cable C.

– Connect cable D. The recommended cross-section of the cable is 1.5 mm2..

For information about the cables to be used when connecting the operator panel to the controller, please refer to the help file for the driver in question.

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

Same day shipment of 1000 parts

My company under the Sales and Marketing Department, technical engineering Department, after-sales service department, the department of comprehensive management. We can help your business with good service.

1. Sales Department 24/7 service. Handles your requests for any PLC DCS products in a timely manner with patience and professionalism.

2. The engineering department ensures that the products have no quality problems. All products will be inspected before shipping.

3. The financial department checks the payment and refund in time.

4. The warehouse department will carefully check the list of goods, carefully pack them, and deliver the goods in time.

5. After-sales Service Department has a full-time after-sales service team, subordinate to the sales department, and users can timely respond to service requests.

Shipping

Superiority products PP885 3BSE069276R1 Compact Product Suite Panel 800 Version 6

| ABB PM865K01 3BSE031151R1 | BANNER LS4ELQ | METSO D100644 |

| GE SR469-P5-HI-A20-E | Schneider Electric XBKH70000002M | YOKOGAWA PW301 |

| GE SR469-P5-HI-A20 | Agilent HP-5517B | ABB GFD233A 3BHE022294R0103 |

| GE SR469-P5-HI-A20-E | PROSOFT PTQ-PDPMV1 | ABB GFD233A103 3BHE022294R0103 |

| ABB S-076N 3BHB009884R0021 | ABB PCD232A 3BHE022293R0101 | BASLER A404K |

| ABB 5SDF1045H0002 | ABB PPD113B03-26-100100 3BHE023584R2625 | NOVOTRON ND32-5610 ND32-5610VS-101-011-31 |

| ABB 3BHL000986P0006 | ABB REF542PLUS 1VCF752000 | A-B 2098-DSD-030-SE/B |

| ABB 5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 | ABB REF542PLUS 1VCR007346 | Bentley 330101-00-08-20-12-05 |

| ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 | PROSOFT PTQ-PDPMV1 | AB 2094-BM01-S/C |

| ABB 5SHY4045L0001 3BHB018162R0001 3BHE009681R0101 GVC750BE101 | ABB PFEA113-65 3BSE050092R65 | METSO ACN CS |

| EATON MP3010 | Honeywell CC-IP0101 51410056-175 | ABB PPC907BE 3BHE024577R0101 |

| TRICONEX 2101 | RELIANCE 61C22A | ABB REF615A_1G HAFNAEFCBGC1BQK11G |

1 Year Warranty

1 Year Warranty