Description

Overview

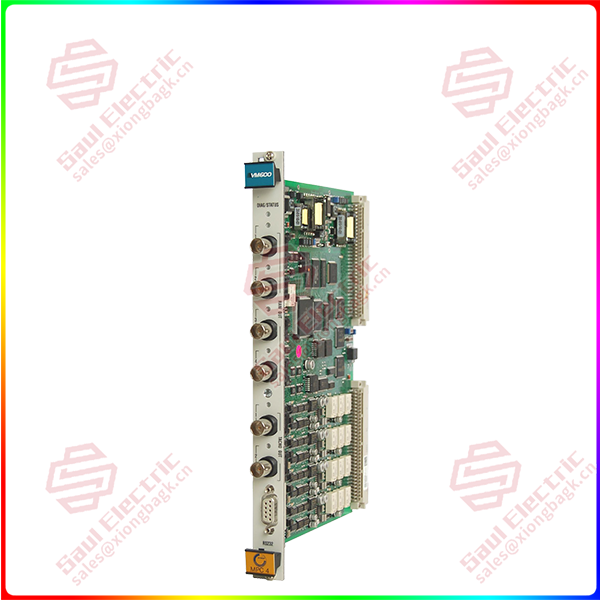

Essential details:VM600 MPC4 200-510-071-113 200-510-111-034 vibration monitoring

Product Description

The VM600 MPC4 200-510-071-113 and 200-510-111-034 are part of a vibration monitoring and analysis system designed to accurately measure and evaluate vibration levels in a variety of industrial applications. These devices are designed to be robust and reliable, capturing and analyzing vibration data to ensure the smooth operation of mechanical equipment.

The VM600 MPC4 vibration measuring instrument has the following features:

Measurement range: The ability to measure vibrations in a specific frequency range, such as 200-510 Hz.

Accuracy: Provides highly accurate vibration measurements for precise analysis and diagnosis.

Connectivity: Connectivity options for data transfer and integration with other systems.

Environmental rating: Designed to withstand dust, humidity and temperature changes in industrial environments.

In addition, the device has the following functional features:

Real-time monitoring: Vibration levels are continuously monitored and measured, allowing any changes or anomalies to be detected in time.

Data Analysis: Provides detailed data analysis and reporting capabilities to aid in fault detection, diagnosis, and predictive maintenance.

Alarm system: The alarm system is triggered when the vibration level exceeds a preset threshold for rapid response and mitigation of potential problems.

Easy to operate: with intuitive user interface and simple operation, easy to use and maintain.

The MPC4 200-510-071-113 is the core component of the mechanical protection system, capable of simultaneously measuring and monitoring up to four dynamic signal inputs and two speed inputs. The MPC4 performs a self-test and diagnostic procedure, and the built-in “OK System” continuously monitors the signal level provided by the sensor, indicating any problems due to a broken transmission line, sensor or transmitter failure.

The VM600 MPC4 VIBRO card/module is a monitoring and analysis device in the protection systems of mechanical equipment such as turbine units in large power plants. It can accurately and quickly detect and analyze the vibration state of mechanical equipment, which helps to prevent potential failures and improve the operation efficiency and reliability of equipment.

The VM600 MPC4 200-510-071-113, as a mechanical protection card for the Vibro-Meter® product line, has a wide range of applications in industrial automation, power system protection and monitoring, mechanical equipment protection and monitoring, and energy management and optimization. It integrates multiple functions to provide comprehensive mechanical protection and monitoring, including dynamic signal input monitoring, multichannel processing, digital processing, real-time monitoring, and programmable alarms and set points.

The VIBRO-METER+VM600 MPC4 is a 6-channel signal interface card for Mechanical Protection Cards (MPC4) that enhances system reliability and uptime, protects expensive equipment from damage, and simplifies installation and maintenance.

VM600 MPC4SIL

Product parameter

The MPC4 200-510-071-113 Machinery Protection Card is the core component of a mechanical protection system, capable of simultaneously measuring and monitoring up to four dynamic signal inputs and two speed inputs.

The card supports the connection of a variety of speed sensors, such as proximity probe based systems, magnetic pulse pickup sensors, or systems that provide TTL signals. Fractional pulse ratios are also supported.

The MPC4 performs a self-test and diagnostic procedure when powered on, and the built-in “OK system” continuously monitors the signal level provided by the sensor, indicating any problems due to a broken transmission line, sensor or transmitter failure.

VIBRO-METER+VM600 MPC4 200-510-071-113 200-510-111-034 is a 6-channel signal interface card for Mechanical Protection cards (MPC4), Features DCS/PLC module, 48-terminal screw terminal strip, EMI protection for all inputs and outputs, 4 relays for alarm signals (software controlled), 32 programmable open circuit outputs to RLC card (jump wire optional), buffered raw, voltage and current vibration outputs, and possible real-time card insertion.

The VM600 MPC4 Vibro Meter is designed to accurately measure and evaluate vibration levels in a variety of industrial applications. It has the characteristics of real-time monitoring, data analysis, alarm system and easy operation.

APPLICATION

Industrial Automation:

The VM600 MPC4 200-510-071-113 is a mechanical protection card in the Vibro-Meter® product line that integrates multiple functions to provide comprehensive mechanical protection and monitoring. Its high flexibility and programmability make it have a wide application prospect in the field of industrial automation.

Power system protection and monitoring:

The system can monitor the vibration of mechanical equipment in real time and provide the corresponding vibration data and parameters, which is crucial for predicting equipment failures, evaluating equipment health and optimizing equipment maintenance plans.

Mechanical equipment protection and monitoring:

VM600 MPC4 VIBRO-METER is widely used in the field of vibration monitoring and fault diagnosis of rotating machinery in power, petroleum, chemical, steel, cement and other industries. Its highly configurable characteristics support a variety of measurement requirements such as relative and/or absolute vibration.

Superiority products VM600 MPC4 200-510-071-113 200-510-111-034 vibration monitoring

| UFC762AE101 3BHE006412R0101 Main board module | IC697CMM742-DC Series 90-70 Communications Module |

| 87199-01 Stator insulation monitor | FC-TSRO-0824 Digital Output Field Termination Assembly |

| MVME55006E-0161R VMEbus Single-Board Computer | MVC3001-4003A ALSPA MV3000 Delta Controller |

| 3500/25 149369-01 Keyphasor module | 6SM57M-3.000 Synchronous Servomotors |

| 3500/92 136180-01 Keyphasor module | 05701-A-0282 Modbus Interface Module Kit RS422/485 |

| 1X00416H01 POWER SUPPLY 24V 300W & 25V 500W OUT DIN-RAIL MOUNT | 3500/91 190782-01 EGD gateway module |

| 5X00241G02 Ovation Westinghouse Controller module | 05701-A-0361 System 57 MODBUS Interface |

| 489-P5-LO-A20 generator management relay | 3500/65 145988-02 16-Channel Temperature Monitor |

| TRICON 3805E TRICONEX Analog Output Modules | 3500/65 172103-01 16-Channel Temperature Monitor |

| 5X00226G02 Ovation Westinghouse Controller module | 136188-02 Ethernet/RS485 Modbus I/O Module |

| MC-4/11/10/400 PowerDrive Motion Controller | PCI-6733 Analog Output Device |

| 2MLR-CPUH/T MasterLogic Programmable Logic Controller | 3ASC25H209 DATX110 I/O board control module |

| KJ4002X1-BA1 Left 8 Wide Vertical Carrier | CE4002S1T2B5 Standard I/O Termination Block |

| S72402-NANANA S700 digital servo drive | CE4005S2B4 Standard I/O Termination Block |

| SCYC55830 58063282A Trigger plate | PCI-4462 Sound and Vibration Device |

| IC697CMM742-DC Ethernet Interface Communications Modules | TU890 3BSC690075R1 compact MTU for the S800 I/O |

| PPC322BE1 HIEE300900R1 Industrial drive function module | KJ4001X1-BE1 12P0818X072 REV:L 8 Wide I/O Carrier with Shield Bar |

| VMIVME-3122 High-Performance 16-Bit Analog-to-Digital Converter (ADC) | KJ2201X1-JA1 Redundant SLS Terminal Block |

1 Year Warranty

1 Year Warranty