Description

Overview

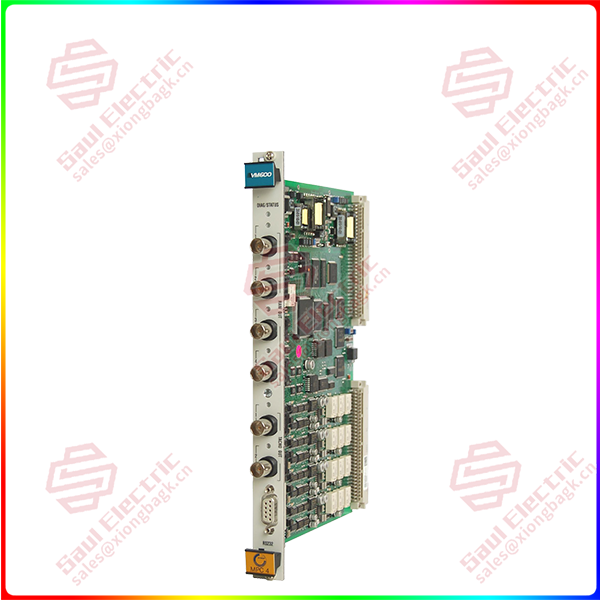

Essential details:VM600 MPC4 200-510-071-113 high-precision multi-channel vibration monitoring

Product Description

VM600 MPC4 product Description

I. Product overview

The VM600 MPC4 is a high-precision multi-channel vibration monitoring system from Vibro-Meter. The system adopts the latest digital signal processing technology, which can monitor and analyze the vibration of the machine in real time, so as to ensure the normal operation of the machine.

Two, the main characteristics

High precision monitoring: VM600 MPC4 uses digital signal processing technology to monitor and analyze the vibration of the machine with high precision.

Multi-channel monitoring: The system supports four dynamic signal channels and two tachometer (speed) channels, all individually programmable, allowing simultaneous monitoring of multiple vibration channels for a more complete understanding of the device’s vibration status.

Programmable filters: The system is equipped with programmable broadband and narrowband filters to meet the vibration measurement needs in different applications.

Real-time fault diagnosis: The VM600 MPC4 can automatically diagnose various mechanical faults and provide accurate early warning information to help users conduct maintenance and maintenance in a timely manner.

Adaptable: Supports a wide range of sensor types, such as acceleration sensors, speed sensors and displacement sensors, to adapt to vibration measurement needs in different applications.

VM600 MPC4SIL

Product parameter

Input channels: 4 channels

Frequency range: 0.5Hz to 10kHz

Measuring range: 0.1mm /s to 50 mm/s

Data sampling rate: 256 times per second

Operating temperature: -20°C to 60°C

Storage capacity: 10,000 data points

Power supply voltage: 24VDC

Iv. Product specifications

Dimensions: 210 x 170 x 75 mm

Weight: 1.5kg

Protection level: IP20

Signal input: BNC connector

Communication interface: RS-485

APPLICATION

The VM600 MPC4 has a wide range of applications, mainly covering various industries that require real-time monitoring and analysis of rotating machinery vibration. Here are a few typical application areas:

Power industry:

In electric power plants, the VM600 MPC4 can be used to monitor the vibration of large rotating machinery such as generators, steam turbines and water turbines. Through real-time monitoring and analysis, potential faults can be discovered in time, equipment damage can be prevented, and the stability and safety of power supply can be ensured.

Petroleum and Chemical Industry:

In the field of petroleum and chemical industry, many equipment such as pumps, compressors, fans, etc., need vibration monitoring. The VM600 MPC4 can accurately monitor the vibration status of these devices, helping engineers to detect equipment failures in time, reduce production interruptions, and improve production efficiency.

Steel and Metallurgical industry:

In the steel and metallurgical industry, the normal operation of rotating machinery such as rolling mills, rolls, electric motors and other equipment is crucial to product quality and production efficiency. The VM600 MPC4 can monitor the vibration of these devices in real time, provide accurate fault diagnosis information, and help engineers take timely measures to ensure the stable operation of the equipment.

Manufacturing Industry:

In a variety of manufacturing industries, including machine building, automotive manufacturing, aerospace and other fields, VM600 MPC4 can be used to monitor the vibration of various rotating machinery such as machine tools, motors, bearings and so on. Through real-time monitoring and analysis, potential faults can be discovered in time to improve the reliability and service life of the equipment.

Cement and Building Materials Industry:

In the cement and building materials industry, the vibration of rotary machinery such as crushers, mills, mixers and other equipment has a great impact on production efficiency and product quality. The VM600 MPC4 can monitor the vibration status of these devices in real time, provide accurate fault diagnosis information, and help engineers take timely measures to ensure the normal operation of the equipment.

In summary, the VM600 MPC4 is suitable for all areas where real-time monitoring and analysis of the vibration of rotating machinery is required. Its high precision monitoring, multi-channel monitoring and real-time fault diagnosis make it widely used in various industries.

Shipping

Superiority products VM600 MPC4 200-510-071-113 high-precision multi-channel vibration monitoring

| 2MLR-CPUHT HONEYWELL CPU HT bus function | 3500/15 127610-01 Bently Nevada Digital input module |

| 177313-01-01 BENTLY NEVATA Vibration monitoring module | 3500/50 133388-02 BENTLY NEVADA Tachometer monitoring module 4 channels |

| PXIE-6556 NI Automatic industrial control module | 3500/40-03-00 176449-01 BENTLY NEVADA Expansion axial position module |

| PFCL201CE ABB Pressure sensor controller | 3500/15 Plastic panel BENTLY NEVADA Ac and DC power supplies |

| MTL BPHM64 Eaton Safety grid base plate | X20CP1586 B&R The core product of B&R’s I/O system line |

| 1794-IF4IXT Allen Bradley Flex I/O 1794 series input module | IC698PSA350 GE High capacity power module |

| 1734-IM4 Allen Bradley POINT I/O 4 Point Digital Input Module | VMIVME 3215-000 GE Computer module |

| 1769-ECR Allen-Bradley Right end cover (ECR) module used together | 201TI GE Microprocessor-based electrical transmitter |

| 136188-02 Bently Nevada Ethernet /RS232 Modbus I/O module | 3500/05-01-02-00-00-01 BENTLY System rack |

| AI02J ABB Analog input module | PM865K02 ABB controller |

| DSSA165 ABB Ac power module | 3500/22-01-01-00 138607-01 BENTLY Transient data interface before and after the size card module |

| PXIe-1073 NI PXI Chassis | IS420UCSBH4A GE Controller module manufactured by General Electric |

| F860-CA HONEYWELL Series C “fieldbus interface module | D201376 METSO Analog input module |

| DSSA165 ABB Ac power module | D201376 METSO Analog input module |

| 125840-02 Bently Power module | IS420UCSBH4A GE Controller module manufactured |

| 125680-01 BENTLY Displacement detection module | IS220PRTDH1A 336A4940CSP6 GE Controller module |

1 Year Warranty

1 Year Warranty