Description

Overview

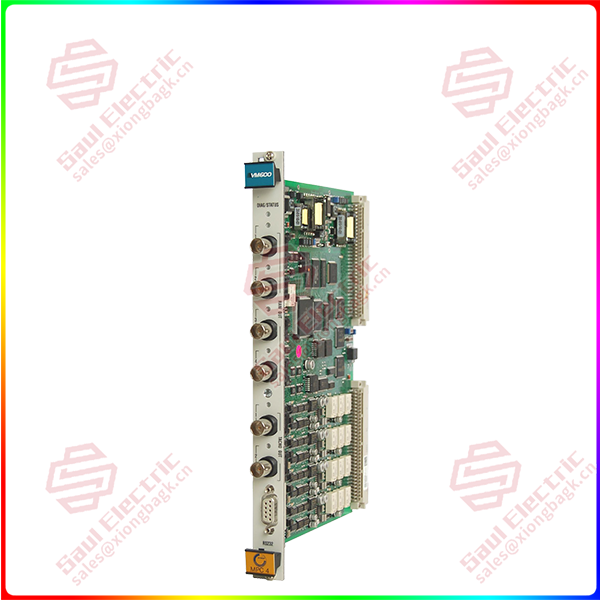

Essential details:VM600 MPC4 200-510-100-034 vibration monitoring instrument

Product Description

VM600 MPC4 200-510-100-034 Product Description

I. Product overview

The VM600 MPC4 200-510-100-034 is a vibration monitoring instrument manufactured by Vibro-meter (now part of the Borger Group). The instrument is a high-precision multi-channel vibration monitoring system, which is widely used in the field of vibration monitoring and fault diagnosis of rotating machinery in electric power, petroleum, chemical, steel, cement and other industries.

Two, the main characteristics

High-precision measurement: Using the latest digital signal processing technology, it can monitor and analyze the vibration of the machine in real time, and provide high-precision vibration data.

Multi-channel monitoring: Support multi-channel measurement function, can simultaneously monitor multiple vibration channels, more comprehensive understanding of the vibration state of the device.

Automatic fault diagnosis: Equipped with high-precision sensors and advanced algorithms, it can automatically diagnose various mechanical faults, and provide accurate early warning information to help users carry out maintenance and maintenance in time.

Multiple sensor support: Multiple sensor types such as acceleration sensors, speed sensors and displacement sensors are supported to adapt to the vibration measurement needs of different applications.

High sampling rate and high resolution: In terms of data acquisition and processing, the VM600 MPC4 has a high sampling rate and high resolution vibration signal measurement to ensure data accuracy.

VM600 MPC4SIL

Product parameter

Input channels: 4 channels

Frequency range: 0.5Hz to 10kHz

Measuring range: 0.1mm /s to 50 mm/s

Data sampling rate: 256 times per second

Operating temperature: -20°C to 60°C (or 0°C to +65°C, depending on product version)

Storage capacity: 10,000 data points

Power supply voltage: 24VDC

Power consumption: 5.5W (Specific power consumption may vary depending on the application)

Structure: modular

Size: 210 x 170 x 75 mm (or package size 168mm x 107mm)

Weight: 1.5kg

Protection level: IP20

APPLICATION

VM600 MPC4 200-510-100-034 Vibration monitoring instrument applications mainly include the following aspects:

Power industry:

The VM600 MPC4 vibration monitoring instrument is widely used in the power industry for vibration monitoring and fault diagnosis of various rotating machinery. It uses advanced digital signal processing technology to monitor and analyze the vibration of the machine in real time to ensure the normal operation and safety of the power equipment.

Petroleum and Chemical Industries:

In the petroleum and chemical industry, the VM600 MPC4 can be used to monitor the vibration of various rotating machinery such as pumps, compressors, fans, etc. Its high-precision measurement and programmable alarm function help in early detection of equipment failures, reducing production disruptions and maintenance costs.

Machinery Manufacturing:

For machinery manufacturing enterprises, VM600 MPC4 vibration monitoring instrument can be used to monitor the vibration state of various mechanical equipment on the production line, such as CNC machine tools, punches, grinders, etc. Through real-time monitoring and early warning, the stability and production efficiency of the equipment can be improved.

Steel and cement industries:

In heavy industries such as steel and cement, the VM600 MPC4 also plays an important role. It can be used to monitor the vibration of large rotating machinery such as mills, crushers, conveyors, etc., to ensure the normal operation and production safety of these critical equipment.

Multi-channel signal processing:

The VM600 MPC4 has multi-channel signal processing capability, which can simultaneously process multiple dynamic signal inputs, such as vibration, displacement, speed, etc. This feature enhances the monitoring capability and flexibility of the system, making it suitable for a wider range of industrial applications.

High precision measurement and programmable alarm:

The VM600 MPC4 uses advanced digital signal processing (DSP) technology to provide high-precision signal analysis. Users can set alarm thresholds and logic to achieve early fault warning according to equipment characteristics and monitoring needs, helping to reduce the risk of equipment failure and production disruption.

In summary, the VM600 MPC4 200-510-100-034 vibration monitoring instrument plays an important role in many industrial fields, helping to ensure the normal operation of equipment and production safety through real-time monitoring and early warning.

Superiority products VM600 MPC4 200-510-100-034 vibration monitoring instrument

| UFC762AE101 3BHE006412R0101 Main board module | IC697CMM742-DC Series 90-70 Communications Module |

| 87199-01 Stator insulation monitor | FC-TSRO-0824 Digital Output Field Termination Assembly |

| MVME55006E-0161R VMEbus Single-Board Computer | MVC3001-4003A ALSPA MV3000 Delta Controller |

| 3500/25 149369-01 Keyphasor module | 6SM57M-3.000 Synchronous Servomotors |

| 3500/92 136180-01 Keyphasor module | 05701-A-0282 Modbus Interface Module Kit RS422/485 |

| 1X00416H01 POWER SUPPLY 24V 300W & 25V 500W OUT DIN-RAIL MOUNT | 3500/91 190782-01 EGD gateway module |

| 5X00241G02 Ovation Westinghouse Controller module | 05701-A-0361 System 57 MODBUS Interface |

| 489-P5-LO-A20 generator management relay | 3500/65 145988-02 16-Channel Temperature Monitor |

| TRICON 3805E TRICONEX Analog Output Modules | 3500/65 172103-01 16-Channel Temperature Monitor |

| 5X00226G02 Ovation Westinghouse Controller module | 136188-02 Ethernet/RS485 Modbus I/O Module |

| MC-4/11/10/400 PowerDrive Motion Controller | PCI-6733 Analog Output Device |

| 2MLR-CPUH/T MasterLogic Programmable Logic Controller | 3ASC25H209 DATX110 I/O board control module |

| KJ4002X1-BA1 Left 8 Wide Vertical Carrier | CE4002S1T2B5 Standard I/O Termination Block |

| S72402-NANANA S700 digital servo drive | CE4005S2B4 Standard I/O Termination Block |

| SCYC55830 58063282A Trigger plate | PCI-4462 Sound and Vibration Device |

| IC697CMM742-DC Ethernet Interface Communications Modules | TU890 3BSC690075R1 compact MTU for the S800 I/O |

| PPC322BE1 HIEE300900R1 Industrial drive function module | KJ4001X1-BE1 12P0818X072 REV:L 8 Wide I/O Carrier with Shield Bar |

| VMIVME-3122 High-Performance 16-Bit Analog-to-Digital Converter (ADC) | KJ2201X1-JA1 Redundant SLS Terminal Block |

1 Year Warranty

1 Year Warranty